4 Easy Facts About Roar Solutions Shown

4 Easy Facts About Roar Solutions Shown

Blog Article

Top Guidelines Of Roar Solutions

Table of ContentsExcitement About Roar SolutionsThe Definitive Guide for Roar SolutionsAn Unbiased View of Roar Solutions

In order to protect installments from a possible explosion a method of analysing and classifying a possibly dangerous area is required. The function of this is to ensure the proper choice and installment of devices to inevitably protect against a surge and to make sure safety of life.

(https://urlscan.io/result/8b06a2f1-9edb-4076-8512-31003b1bcc3a/)

No tools should be installed where the surface temperature of the equipment is higher than the ignition temperature of the provided danger. Below are some typical dirt hazardous and their minimum ignition temperature. Coal Dust 380C 225C Polythene 420C (melts) Methyl Cellulose 420C 320C Starch 460C 435C Flour 490C 340C Sugar 490C 460C Grain Dust 510C 300C Phenolic Resin 530C > 450C Aluminium 590C > 450C PVC 700C > 450C Residue 810C 570C The likelihood of the threat being existing in a focus high enough to cause an ignition will certainly differ from place to place.

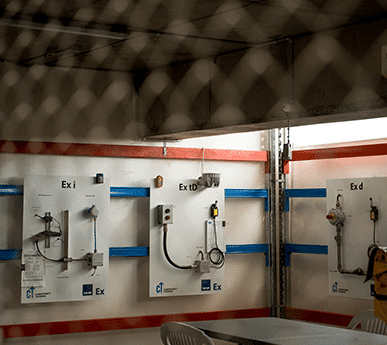

In order to identify this risk an installment is separated right into locations of threat depending upon the amount of time the dangerous is present. These areas are referred to as Areas. For gases and vapours and dirts and fibres there are three areas. Zone 0 Zone 20 A dangerous ambience is very likely to be present and might be present for lengthy durations of time (> 1000 hours annually) or even continually Area 1 Area 21 A dangerous ambience is possible yet not likely to be existing for extended periods of time (> 10 450 C [842 F] A category of T6 implies the minimum ignition temperature level is > 85 C [185 F] Unsafe location electrical tools perhaps designed for use in greater ambient temperatures. This would certainly suggested on the rating plate e.g. EExe II C T3 Ta + 60C( This indicates at 60C ambient T3 will not be gone beyond) T1 T1, T2, T3, T4, T5, T6 T2 T2, T3, T4, T5, T6 T3 T3, T4, T5, T6 T4 T4, T5, T6 T5 T5, T6 T6 T6 A T Class rating of T1 suggests the maximum surface area temperature level generated by the tool at 40 C is 450 C. Presuming the associated T Course and Temperature level rating for the tools are ideal for the area, you can always make use of an instrument with a much more stringent Division rating than required for the location. There isn't a clear solution to this inquiry regrettably. It really does rely on the kind of tools and what fixings need to be brought out. Equipment with certain test treatments that can't be carried out in the field in order to achieve/maintain 3rd party rating. Need to come back to the manufacturing facility if it is before the tools's service. Field Fixing By Authorised Personnel: Challenging screening may not be required nonetheless certain treatments may need to be complied with in order for the devices to keep its 3rd event rating. Authorised workers have to be employed to carry out the work properly Fixing must be a like for like replacement. New element continue reading this should be thought about as a direct substitute calling for no unique screening of the devices after the repair service is full. Each tool with a hazardous rating should be reviewed separately. These are detailed at a high degree below, but also for more comprehensive info, please refer directly to the standards.

Everything about Roar Solutions

The tools register is a comprehensive data source of devices records that includes a minimum collection of fields to determine each thing's place, technical criteria, Ex-spouse category, age, and ecological data. The ratio of Comprehensive to Close inspections will certainly be identified by the Tools Threat, which is examined based on ignition risk (the possibility of a resource of ignition versus the chance of a flammable environment )and the hazardous location category

( Zone 0Area 1, or 2). Executing a durable Risk-Based Evaluation( RBI )technique is essential for ensuring conformity and security in managing Electrical Equipment in Hazardous Locations( EEHA).

Top Guidelines Of Roar Solutions

In regards to eruptive danger, a dangerous location is a setting in which an explosive atmosphere is existing (or may be expected to be existing) in quantities that require special preventative measures for the building, installation and use tools. high voltage courses. In this write-up we check out the challenges encountered in the work environment, the risk control procedures, and the called for competencies to function safely

It issues of modern life that we produce, store or deal with a variety of gases or liquids that are regarded combustible, and a variety of dirts that are deemed combustible. These materials can, in certain problems, create explosive ambiences and these can have major and unfortunate consequences. The majority of us recognize with the fire triangle remove any type of among the three components and the fire can not take place, however what does this mean in the context of unsafe locations? When breaking this down right into its simplest terms it is basically: a mix of a specific quantity of launch or leak of a specific compound or product, combining with ambient oxygen, and the presence of a source of ignition.

In the majority of instances, we can do little regarding the levels of oxygen airborne, but we can have significant influence on sources of ignition, for instance electrical equipment. Dangerous areas are documented on the unsafe location category illustration and are recognized on-site by the triangular "EX-SPOUSE" sign. Below, among other key information, areas are divided right into 3 types depending upon the threat, the probability and duration that an explosive atmosphere will certainly exist; Area 0 or 20 is deemed the most hazardous and Area 2 or 22 is deemed the least.

Report this page